What is the Equipment for Aseptic Preparation?

The equipment for aseptic preparation provides a fully secure and hermetically sealed containment area for preparations. Aseptic preparations can be handled, stored and packaged in a completely sterile environment.

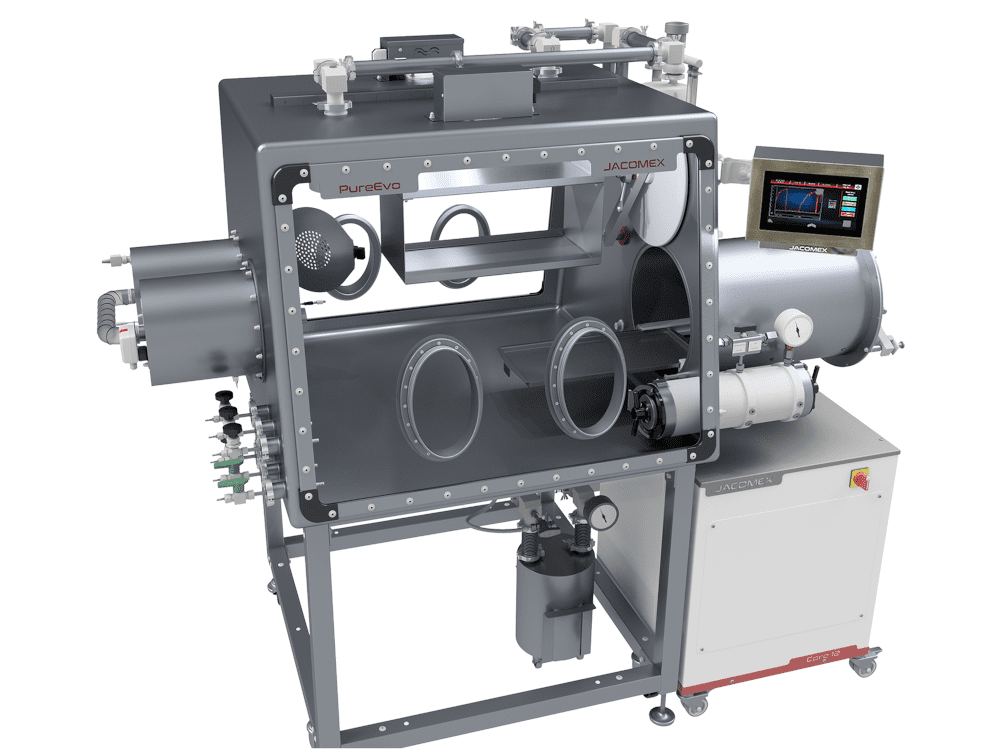

Aseptic preparation equipment has transparent walls where handling gloves are attached. It also incorporates a transfer system to allow products to be removed or inserted.

The sole purpose of aseptic preparation equipment is to ensure that product containment is maintained, that personnel are protected and that contamination risks are minimised. Dosing and weighing operations and the handling of advanced therapy medicinal products require the use of aseptic equipment.

In the pharmaceutical field, containment equipment has the following general characteristics

- Negative or positive pressure ;

- Operation, with or without internal storage, in just-in-time mode;

- Positioning of workstations side by side or opposite each other;

- Turbulent, laminar or unidirectional flow ventilation;

- Safe transfer systems.

- HEPA or ULPA filtration.

Specific elements can also be integrated into the equipment, depending on its application:

- Laboratory equipment (precision balance, incubator, centrifuge, etc.);

- Equipment for powders (sifter, grinder);

- Equipment specific to the pharmaceutical field (freeze-dryer).

- It is essential to comply with FDA, PIC/S and ISO standards, 21 CFR part 11, GAMP5 and GMP when designing equipment for aseptic preparation.

Aseptic Equipment By Jacomex

Jacomex is a world-renowned designer and manufacturer of aseptic equipment, glove boxes and containment isolators. The implementation of your projects is made easier thanks to the high performance means developed by our design office and our qualified personnel.

The equipment we develop meets every type of need: equipment for aseptic preparation, glove boxes, gas purification systems, etc. Customised, standard or modular equipment can also be proposed to you while respecting the high level of constraints for your processes and your specifications. You can use the customised equipment that we produce at each stage of your product’s manufacturing process. The management of your project is personalised and is carried out by our specialists. You will also benefit from technical support. The requirements of the most stringent standards and guidelines are fully complied with in the design of your aseptic preparation equipment. When defining your equipment, our consultants and engineers will support you by taking into account your internal processes, your specific needs and the sanitary constraints.