Factory Acceptance Test (FAT)

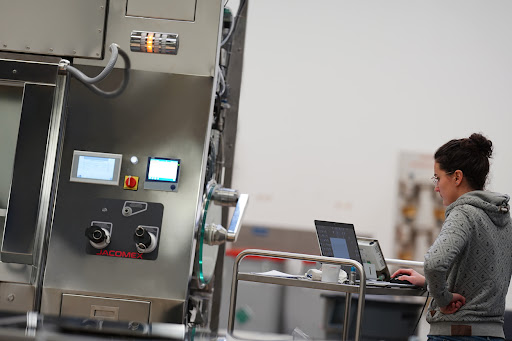

The purpose of the Factory Acceptance Test (FAT) is to demonstrate that the equipment conforms to the requirements expected by the customer and that it functions correctly under normal conditions of use.

This FAT is carried out in our facilities near Lyon in Dagneux in Ain. Jacomex's project manager and quality teams work alongside our customers to validate the protocol that will be jointly established. This test, in addition to the verification of the conformity of the equipment, will allow customers to have a solid grounding in the functions of the system.

In particular, this may relate to:

- General functional check

- Checking that the transfer airlock(s) and other transfer systems operate correctly

- Checking that the flip-up front panel works correctly

- Checking that the pressure control works

- Checking that the alarms function correctly

- Verify that the decontamination system is integrated correctly

- Component control

- Verification of locations and attendance

- Coding verification

- Condition and cleanliness

- Inspection of surface conditions (Ra)

- Factory inspection of glove box tightness (ISO 10648-2)

They Trust Jacomex Solutions

Many customers from a variety of industries have trusted Jacomex to design and manufacture their glove boxes, insulators and air purification systems.