Perovskite, organic photovoltaic (OPV) and OLED

When future technologies require pure & inert atmosphere.

Making Organic Light Emitting Diod (OLED), OPVs and perovskite can be manufactured with quite similar processes involving wet coating and evaporating steps in an inert atmosphere and preferably particle free.

Learning from these processes, Understanding the critical characteristics for our customers, so as to provide the best results and protects their research and development, Jacomex offers complete solutions integrated within inert glovebox systems removing traces (<1ppm) of Oxygen (O2), Moisture (H2O), and optionally Nitrogen (N2).

Main applications

- Wet coating

- Spincoater

- Slot dye

- Evaporation coating

- Encapsulation

- Temperature curing

- Solar simulator testing

Environmentally friendly by design – Energy Saving for all!

Preserving our environment should not be a compromise. Therefore, the Energy Saving Mode is included and offered free of charge on all the Jacomex Gloveboxes.

- Standard consumption = 198 Watts

- Energy Saving Mode = down to 31 Watts

Standard configuration

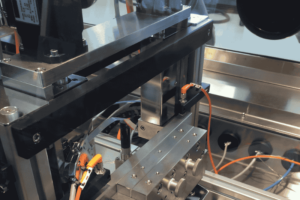

Tailored solutions and seamless third-party process integrations

- Bottom integrated Spin coater

- Table to spin coater, precision scales, mixing devices

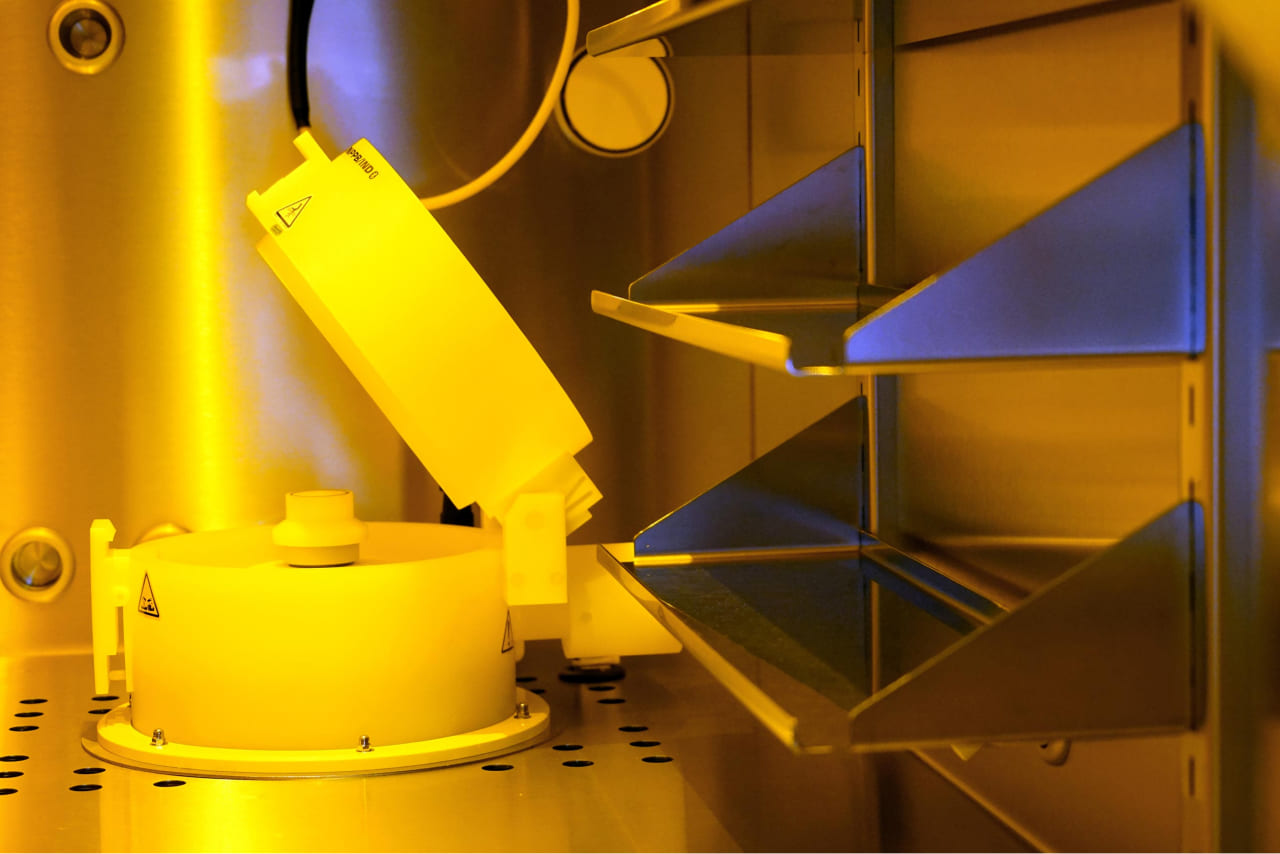

- PVD and evaporator integration

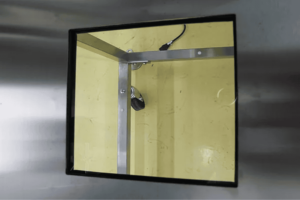

- Solar simulator and quartz windows

- Drying ovens

- Encapsulation

- Temperature controls

- Laminar flow

- Customer process development/integration

Within custom designed and manufactured glovebox systems.

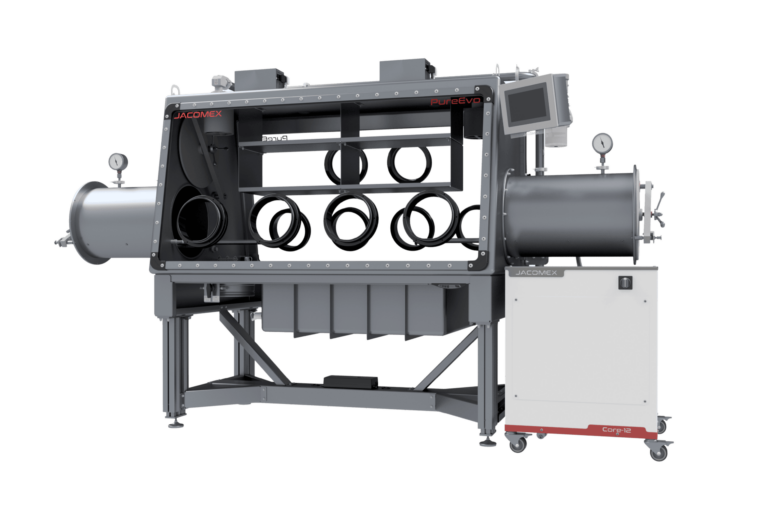

Purified Inert Gas Glovebox Range Common Standardized Configurations.

- Modular design 2,3, 4 glove workstations

- Single or face to face options

- Purified Argon or Nitrogen gas operation

- Nitrogen removal management

- Solvent trapping, disconnectable or regeneratable

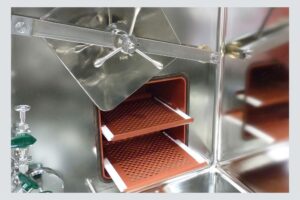

- Heated vacuum antechambers, Ø150mm – Ø400mm

- User Friendly HMI, User management and 2 months data recording

- Low maintenance for reduced Total Cost of Ownership (TCO)

- 3 year limited warranty

Equipment and features

Recommanded Features and Options for Perovskite Applications

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG