Equipment for Glove Boxes

All Jacomex Equipment

(-/+) Pressure gauge

230V hermetic feedthrough

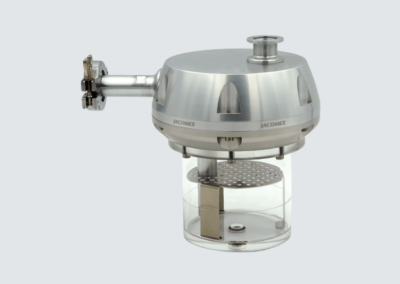

300m3/h Filter Housing

3D Printer (Additive Manufacturing)

4x banana hermetic feedthrough

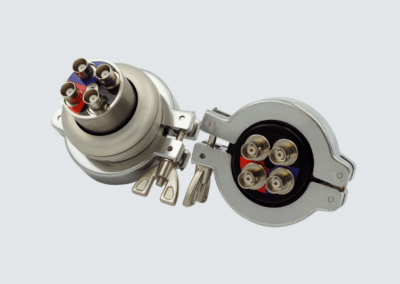

4xBNC hermetic feedthroughs

50-70m3/h Filter Housing

50m3/h activated carbon Filter (radionuclides)

50m3/h activated carbon filters (solvants)

5m3/h Hydraulic guard

Ø100 Vacuum Chamber O-ring

Ø150 Vacuum Chamber O-ring

Ø156 glove securing ring

Ø250 Door lever O-ring

Ø250 Vacuum Chamber O-rings

Ø400 Vacuum Chamber O-rings

Activated carbon filter 50m3/h (acids)

Air conditioning for Glove Boxes

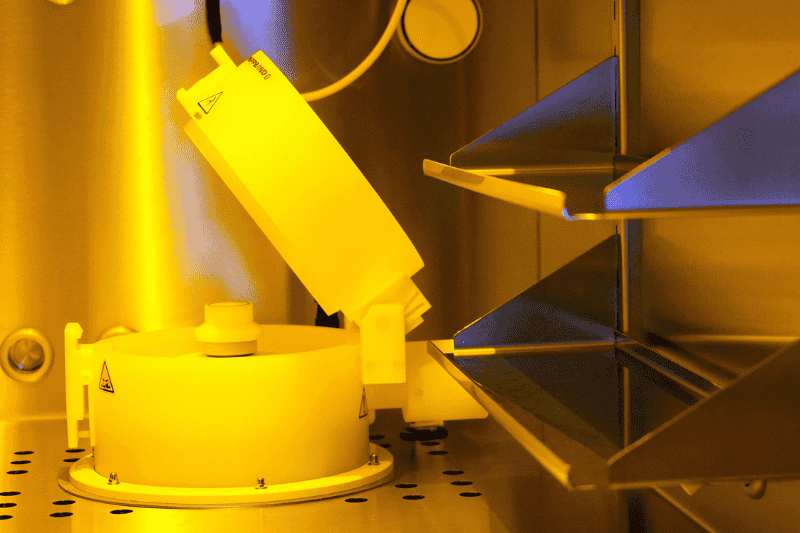

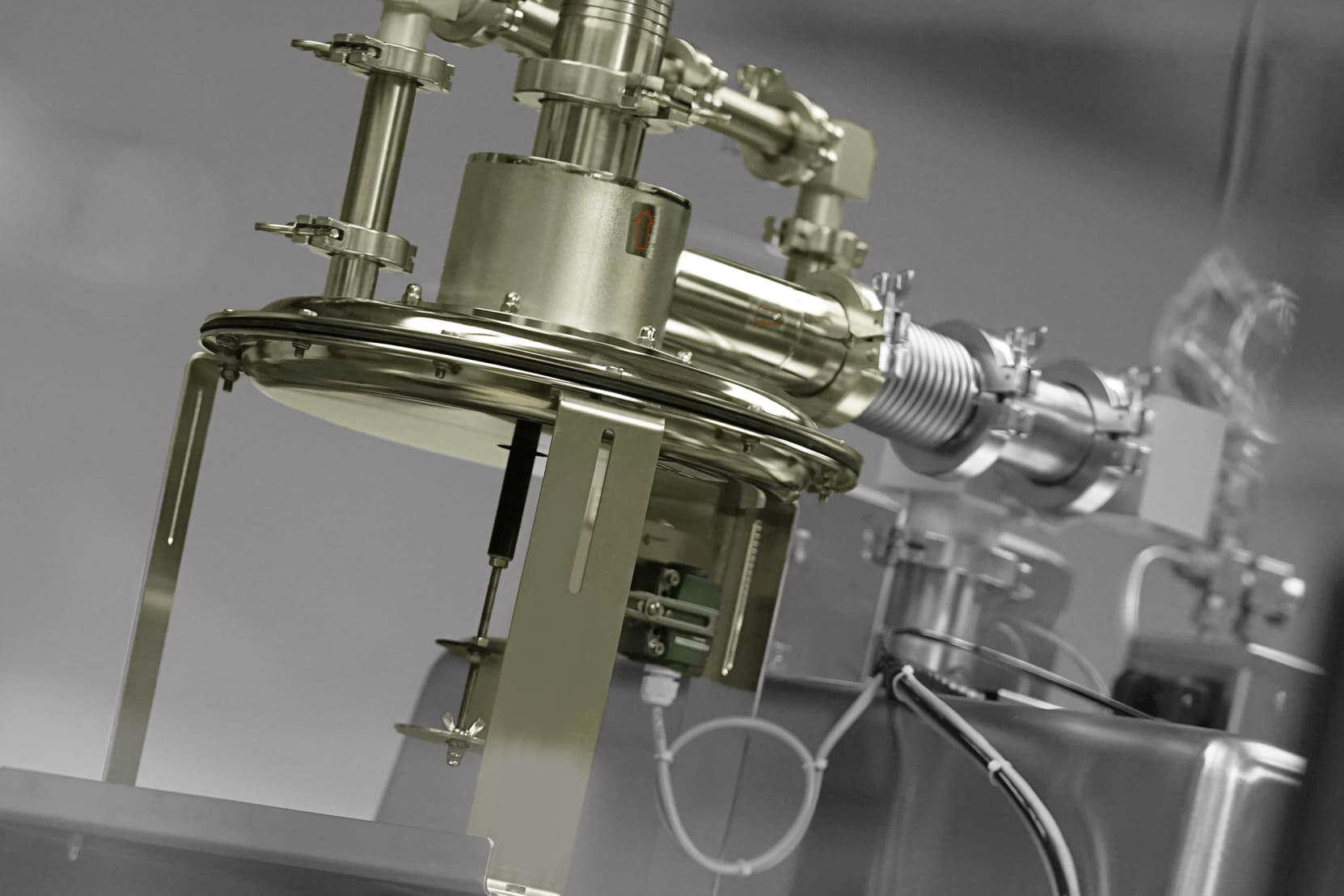

ALD (Atomic Layer Deposition) for Glove Box

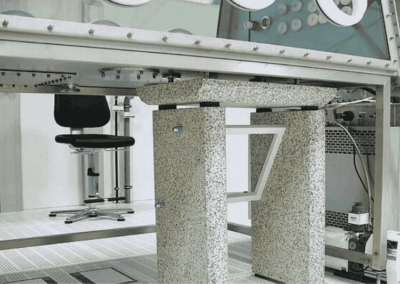

Anti-vibration Table for Glove Boxes

Armrests

ATEX Autonomous Extraction Fan

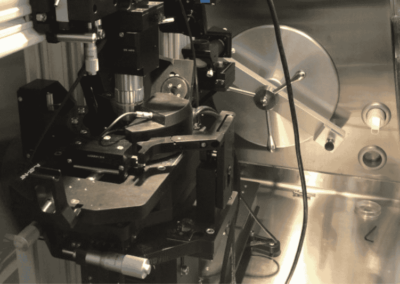

Atomic Force Microscope (AFM) for Glove Box

Automatic Door for Glove Box

Jacomex Equipment by Category

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.

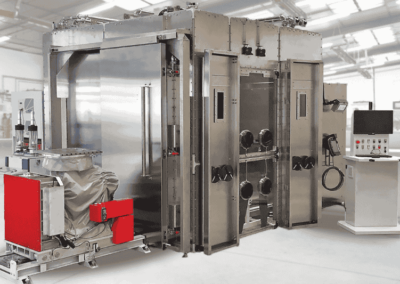

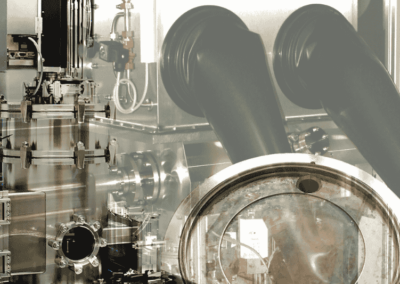

Glove boxes enable the use of materials in research, development and production while also guaranteeing that the glove box remains waterproof. They preserve the functional integrity of laboratory equipment, measurement and characterization instruments, tools and robots under conditions specific to each glove box or containment enclosure box.

Jacomex is an expert in gas purification designed for the removal of H2O and O2. We have developed a wide range of purification units operating in "Continuous Energy Saving" mode to cover most needs and meet the most demanding requirements.

Some of the optimization options include protecting your installation against the risks of corrosion, improving its internal cleanability, overcoming ESD risks and, finally, ensuring the safety of operators.

Jacomex’s corporate culture is based on values derived from our experience: bringing authenticity to our boards, offering realistic technical solutions, ensuring the reliability and sustainability of our facilities, and assisting you effectively on a daily basis.

The Modular and Made-to-measure Jacomex

We adapt our products and technical solutions to suit the complexity of your project . The integration of standard instrumentation can be delivered using a standardized modular glove box such as a GP(concept), G(box) or G(safe).

The interfacing or installation of more sophisticated machines in a glove box, such as presses, industrial ovens or robots will require the involvement of our design team to develop your tailor-made solution.

Particular attention will be paid to dimensions, ergonomics, mechanical resistance or the risks of temperature variations.

Our R&D and Innovation department also develops equipment to:

- Secure your workspace,

- Improve handling ergonomics and comfort,

- Optimize operations and processes in and around glove boxes.