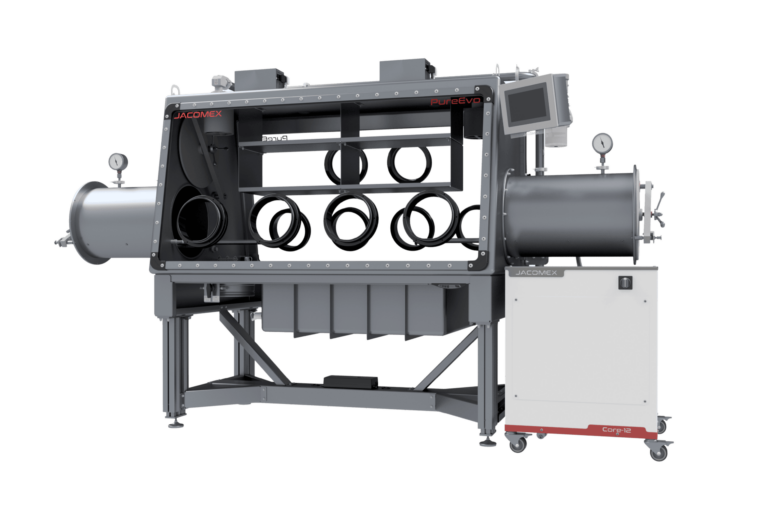

Glove boxes for welding applications

Jacomex has always been a reference in the field of argon support, as a major supplier of players and contractors in the aerospace sector.

Titanium, molybdenum and other metals which are very sensitive to high temperature oxydation require special attention during the welding processes.

Where guaranteeing the welding environment pure and free of Oxygen (traces in ppm), so that no browning or brittleness phenomenon occur, and to ensure the best mechanical properties to the welds, the Jacomex purified gloveboxes and large enclosures integrate the welding process, making it highly repeatable and reliable.

Main applications

- Naval

- Electronic

- High performance Automotive Industry

Standard configuration

Our offer

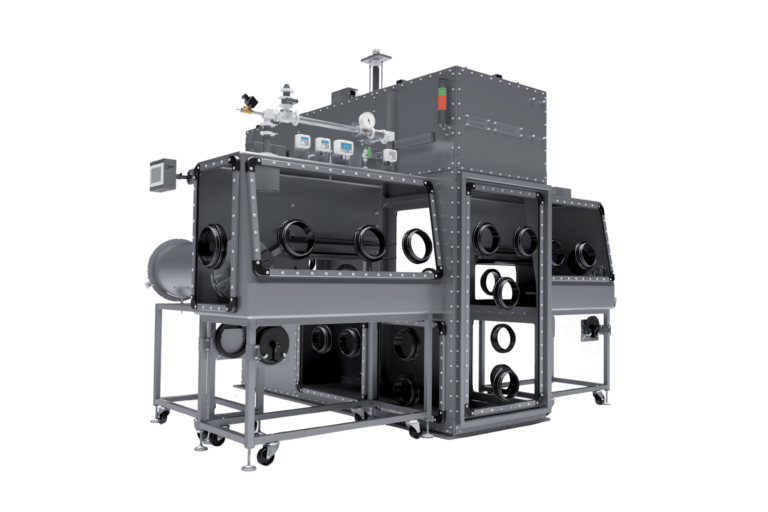

- A range of standardized cost effective glovebox systems (PURE)

- Large bespoke inert gas englosures to fit the client’s dimension raquirements (G-MEGA)

- TIG Welding under purified argon gas

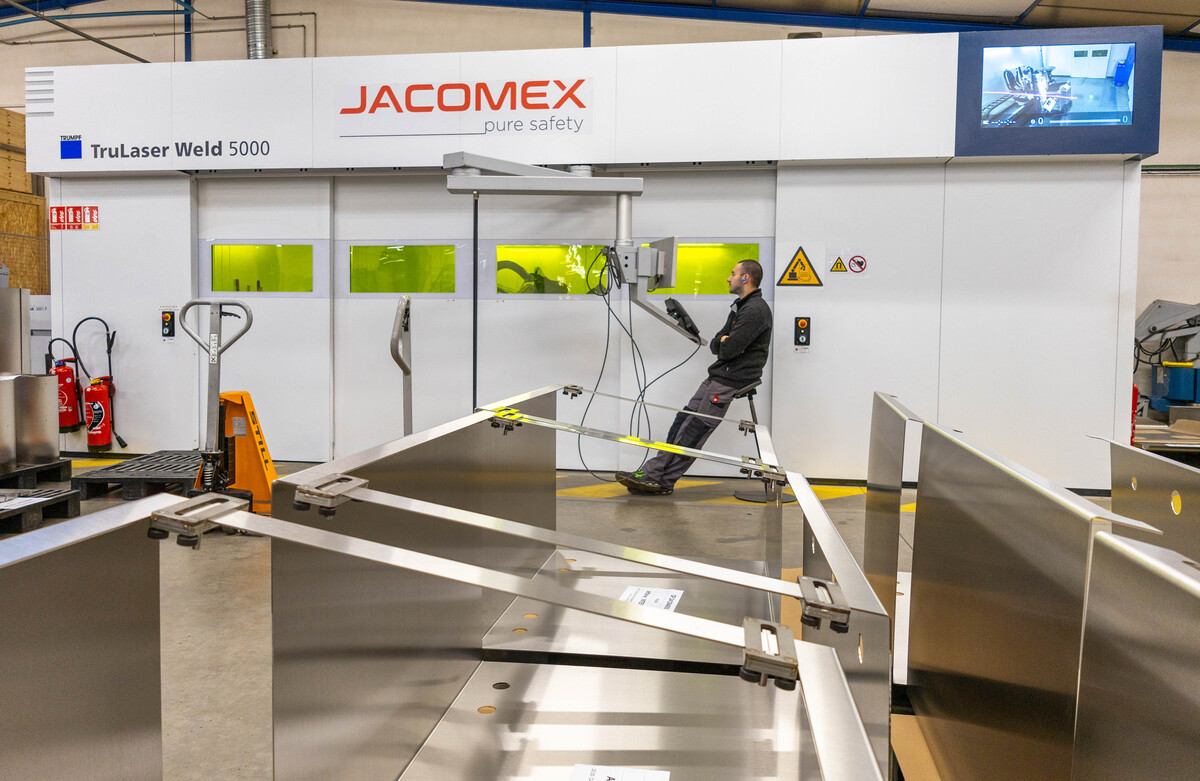

- Lazer Welding process integration in purified argon

- Construction material in 304L or 316L for no carbon cross contamination

- Rugged industrial design

- Fully enclosed welding process requiring no additional gas input, lowering the gas consumption, and garanteeing the highest reproductibility of the welds

- Customizable loading and unloading antechamber sizes.

Standardized Features For Cost Effective Modular Solutions

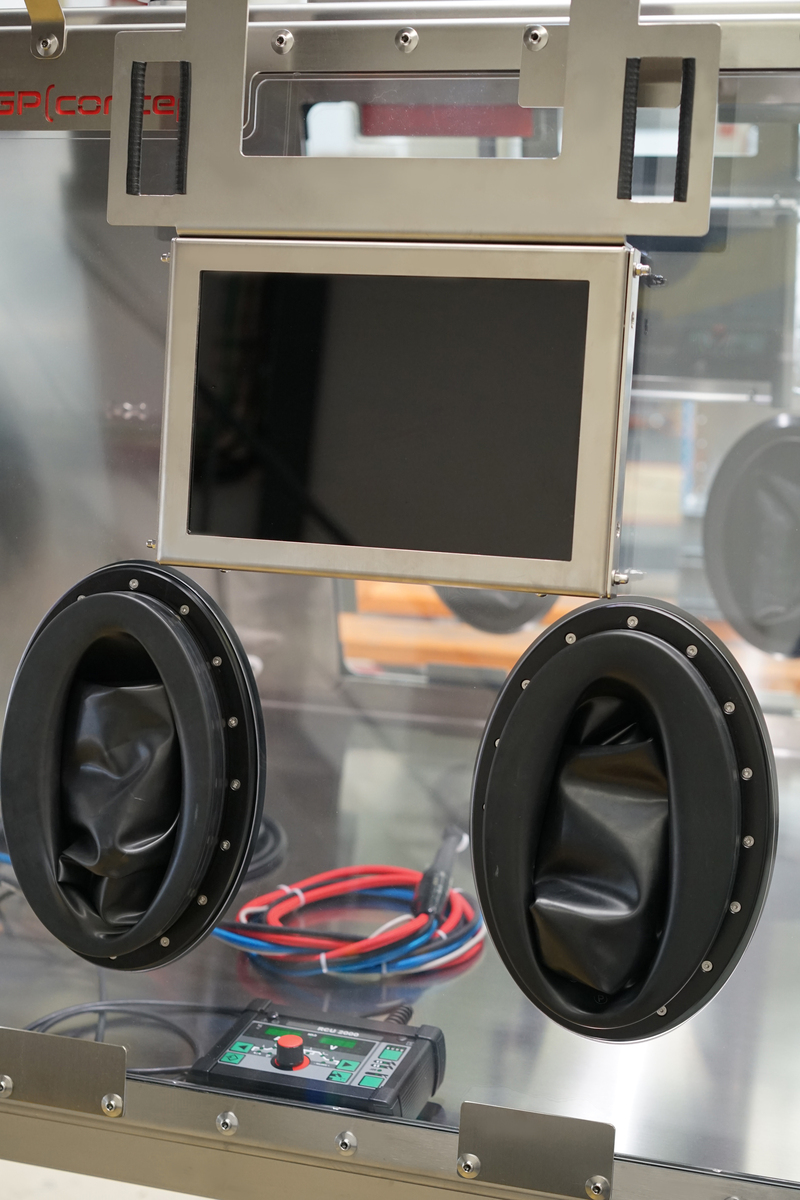

- Standard 2, 3 or 4 gloveports and entry / exit vacuum airlock systems

- Standalone « Core » gas purifier for argon, nitrogen, helium (or a mix thereof).

- Negative or positive relative pressure operation

- Panel integrated welding glass (option)

- Integration of customer welding torches (option)

- Fumes and dust filtration

- Active confinement safety for user and environment protection (option)

- Single faced or double faced working stations

- Laser protection window (option)

Large Industrial Welding Enclosures

- Fully custom design of large volumes (typically 15 to 50m3 and up)

- Dedicated super duty standalone CORE gas purifier

- Dedicated JACOMEX project and engineering team

- Third party process and OEM integration

- Special loading and unloading antechamber systems for high productivity

- Special filtrations: Fumes, gases

- Inner conveyers (option)

- Active confinement system for user safety (option)

- Integrated overhead crane (option)

Equipment and features

Recommanded accessories for welding application

Certifications

ISO and European quality standards

Jacomex is proud to uphold the highest industry standards, with certifications including ISO 9001:2015 for quality management, and ISO 10648-2 for containment enclosures and glove boxes. Additionally, we ensure compliance with EN 60439-1, a self-certification CE standard, reflecting our commitment to safety and reliability.

ISO 9001:2015

Quality Management Systems

Certification and CE Marking

Compliance with European Union regulatory requirements

ISO 10648-2

Tightness standard for containment vessels

ISO 3834

Welding Quality Management System for TIG and YAG