Cosmetic Equipment

Designed in collaboration with famous Cosmetic brands, the tube testers are designed to test the resistance of empty or full tubes while vacuum boxes allow tightness tests to be carried out on full tubes.

Equipment and features

Cosmetic Equipments by Jacomex

Testing and Control Equipment Play a Crucial Role in the Cosmetics Industry and Laboratories

Testing and control equipment are essential in the manufacturing and development of cosmetic products, whether in industrial or laboratory settings. These specialized tools are designed to meet the specific needs of the cosmetics industry, ensuring the quality of packaging for cosmetic products. While they are commonly used in cosmetics, their demand is also growing in the pharmaceutical and food industries.

Jacomex has developed devices that allow for quality control of packaging and containers (bottles, jars, tubes, sachets, etc.) directly on production lines in both the cosmetics and pharmaceutical fields.

Benefits of Cosmetic Packaging Quality Testing and Control

Cosmetic packaging quality testing and control are essential steps in the quality assurance process for cosmetic products in both industry and laboratories. These tests are designed to evaluate the performance and durability of packaging used for cosmetic products, such as bottles, jars, tubes, boxes, and sachets.

Cosmetic testing equipment for industries and laboratories dedicated to packaging tests and trials primarily ensures the leak-tightness of all types of cosmetic containers. These tests verify the resistance of packaging and help prevent the risk of leaks. Additionally, they ensure the stability of formulations and the preservation of the quality of cosmetic products throughout their lifecycle. Ultimately, this contributes to consumer safety and helps maintain the products in optimal conditions.

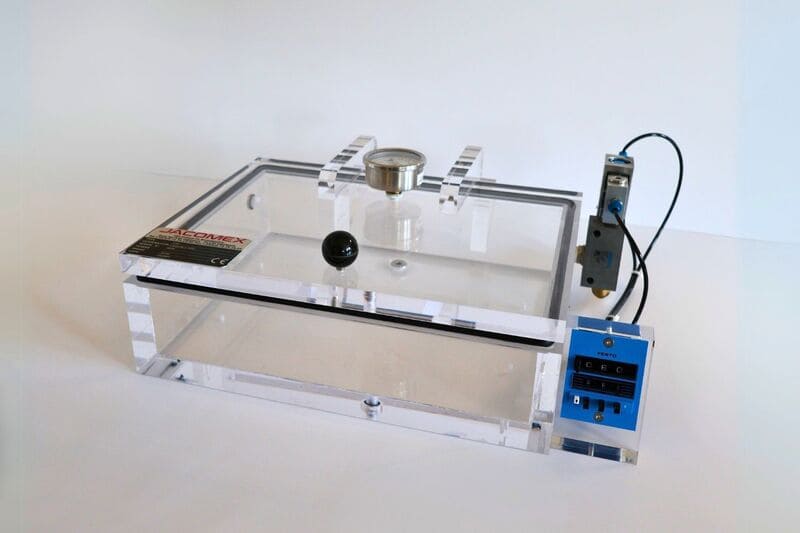

Cosmetic Testers for Industry and Laboratories: Vacuum Chambers for Leak Testing of Container Closures

Jacomex vacuum chambers are essential equipment for the cosmetics and pharmaceutical industries. These chambers create a low-pressure environment to test the leak-tightness of container closures. By vacuum-sealing the chamber with the tested container, it becomes possible to quickly verify the integrity of the bottle and sealing system directly on a production line.

The chamber settings (pressure and test duration) can be adjusted and pre-set according to the requirements of major industry players to ensure compliance with their specifications. As a result, vacuum chambers can be used by cosmetic product manufacturers, packaging manufacturers, and cosmetics laboratories alike.

Tube Crushing Testers to Assess the Strength of Tube Seals

Jacomex tube crushing testers are vital tools used in the cosmetics industry and laboratories to evaluate the strength and integrity of packaging for products such as cream, gel, or toothpaste tubes. These devices are designed to simulate extreme real-world conditions that tubes may encounter during consumer use.

The crushing testers apply controlled force to the tubes to determine their ability to withstand compression, prevent leaks, and maintain the quality of their contents. These tests play a critical role in the development and validation of cosmetic packaging, ensuring consumer safety and satisfaction.

They Trust Jacomex Solutions

Many customers from a variety of industries have trusted Jacomex to design and manufacture their glove boxes, insulators and air purification systems.

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.