ALD (Atomic Layer Deposition) for Glove Box

Overview

ALD (Atomic Layer Deposition)

Description

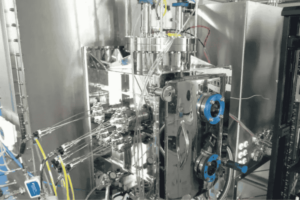

- Atomic Layer Deposition (ALD) is a process for depositing thin atomic layers;

- ALD is a particular form of CVD (Chemical Vapour Deposition). The main difference between ALD and generic CVD is the sequential, and not simultaneous, introduction of the precursors into the reaction chamber;

- Although slower than other techniques, the process provides a better structural quality;

- Allows deposition of TiO2, Al2O3, SiO2, ZnO, MgO, NiO, SnO2, Nb2O5 layer by layer.

Technical specifications - Information

|

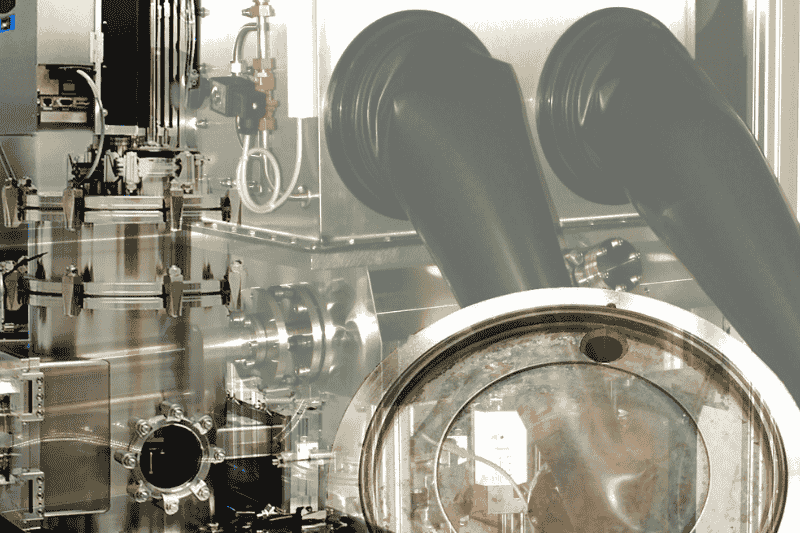

External frame with an integrated glove box via a stainless-steel flange.

|

|

The ALD can be integrated on the floor, on the back or on one side of the glove box depending on the models.

|

|

Compatible with most models designed with an adequate interface.

|

What Are the Thin Film Deposition Techniques Applications?

The fields where thin film deposition techniques are most widely used are the production and development of components for energy storage and conservation, semiconductors and nanotechnology.

Therefore, in the field of organic photovoltaic cells, lithium batteries, OLEDS or sensors, gloveboxes have to integrate many instruments that can be interfaced by a flange. Thus, a thin film of material, generally with a thickness of a few nanometers, can be deposited while being protected from oxygen and moisture.

Some Thin Film Deposition Techniques

Different types of equipment are available for atomic layer deposition (ALD) including:

- Slot Die deposition equipment, allowing for deposition on large substrates;

- Vacuum evaporation equipment, allowing for the evaporation of a metallic or organic material and the deposition of a thin layer on the surface of a wafer or a substrate;

- Inkjet printing equipment for the deposition of a thin layer of functional liquids on the surface of various substrates which can reach larger dimensions (dielectric ink, conductive ink);

- Equipment for the deposition of thin layers by spincoating, more particularly dedicated to small substrates or wafers of reduced size.

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.

Contact form

Need help or an offer? Contact us