Electropolishing for Glove Boxes

Overview

Electropolishing

Description

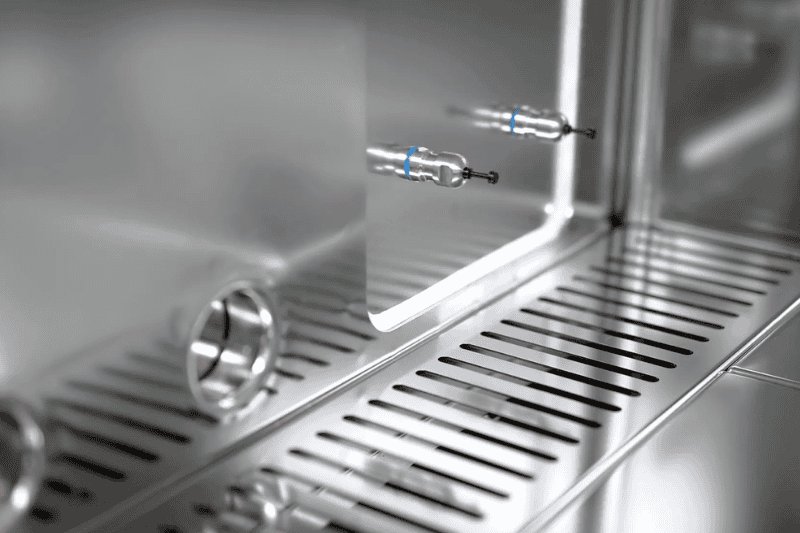

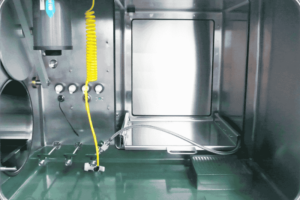

Electropolishing is a highly sought-after surface finish for pharmaceutical isolators as well as being highly valuable in other fields such as heavy industry, nuclear and nanotechnology sectors etc. as it increases the cleanability of the workspace and optimizes surface decontamination. After mechanical polishing, the glove box and its components are dipped in an electrolytic bath which gives them a shiny or satin finish.

Technical specifications - Information

Technical specifications of the electropolishing:

|

Surface roughness Ra < 0.2.

|

|

Possible treatment for our glove boxes, transfer systems, ovens and other equipment.

|

Combined with a one-piece design with rounded corners, electropolishing is a perfect solution for solving all cleanability problems as well as reducing the risk of cross-contamination and keeping the volume and the work surface in a lasting state of cleanliness.

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.

Equipment and Features

See our related products

Contact form

Need help or an offer? Contact us