Glove Boxes with Joule Effect Vacuum

for PVD Thin Film DepositionProject Results:

Joule vacuum evaporation frames integrated in a glove box under controlled atmosphere are useful in the deposition of thin layers of metallic materials (Au, Pt, Ti, Cr, Al, Li...) and oxides (SiO2, HfO2, Al2O3, ...). These thermal evaporators are widely used for metallization, e.g. for photovoltaic cells and detectors, for electrode deposition (ohmic contacts), e.g. for batteries and OLED organic electronics and for refractory thin films and optical layers.

The installation described below is an example of a solution that Jacomex delivered in partnership with the Alliance Concept for the deposition of thin layers of metallic materials in purified glove boxes.

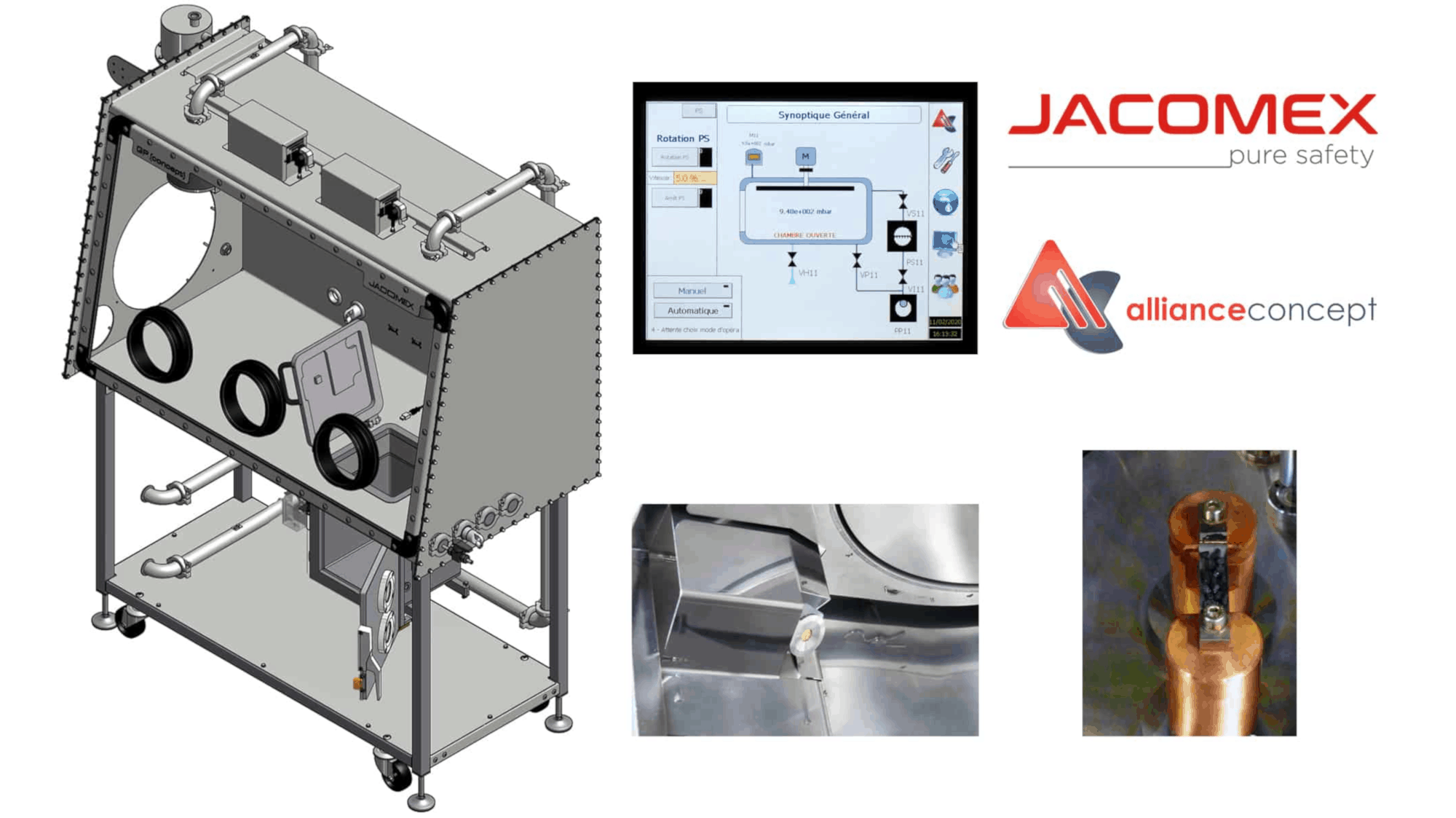

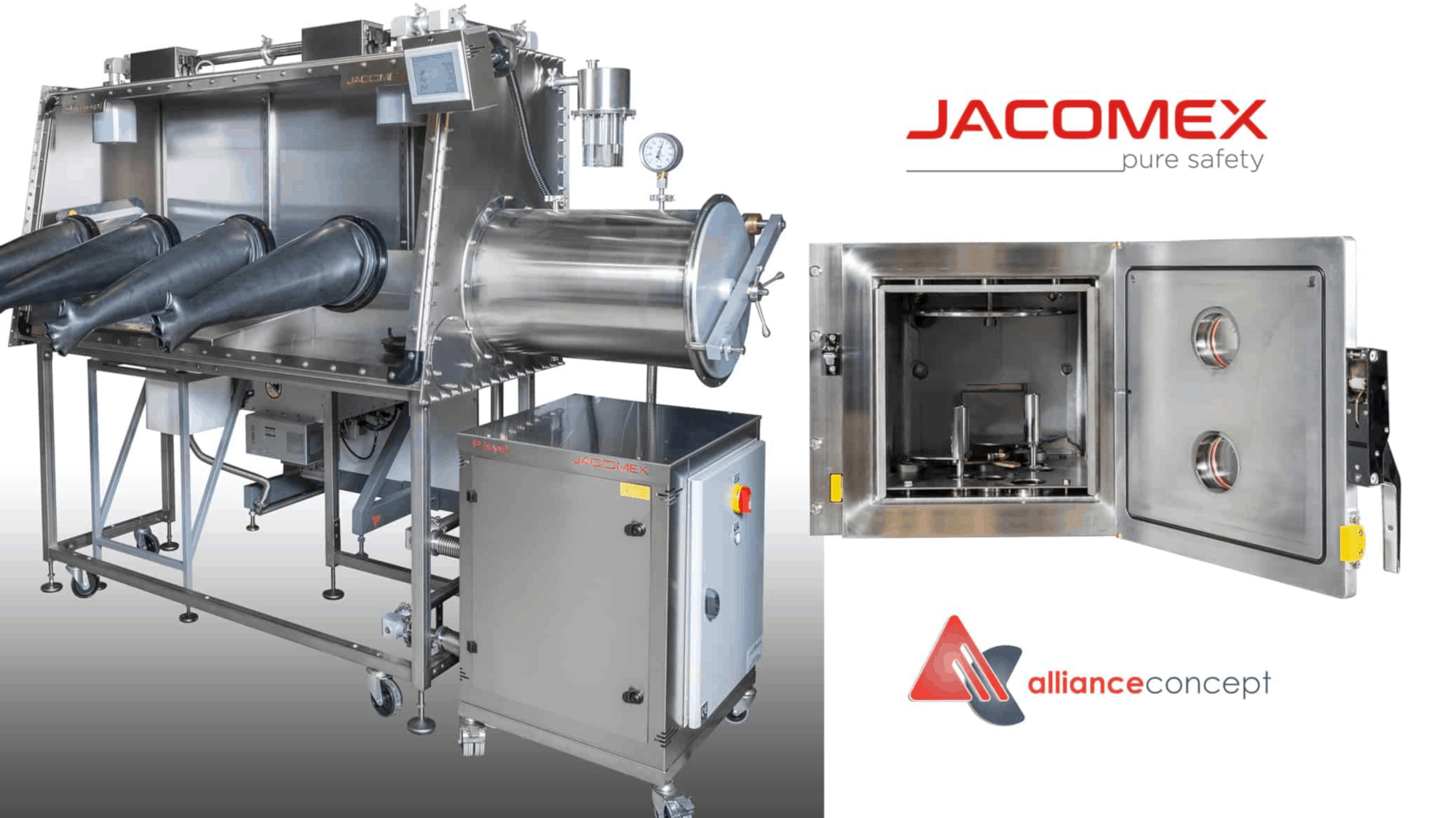

PUREEVO Glove Box

The model is available in different lengths - 2 gloves, 3 gloves, 4 gloves and two configurations - single-sided or double-sided.

The glove box is equipped with two vacuum airlocks, usually Ø400 and Ø150mm, connected to a vacuum pump (rotary vane primary pump or dry pump). Depending on the requirements, the airlocks can be produced in a heated version as well. In case of connection to another glove box that is used in the phases of deposition, preparation or characterization of substrates, it is possible to provide T vacuum airlocks that allow the introduction of materials from outside in a glove box as well as the transfer of samples from one glove box to the other.

The PUREEVO glove box is equipped with a P(sys) purification unit for continuous removal of traces of moisture and oxygen from the working volume at levels of 1 ppm or less. The purification units of the P(sys) range are high capacity gas scrubbers (N2, Ar) with variable flow rate circulator, automatic regeneration, automatic pressure regulation and 24/24 continuous Energy Saving mode. Other features (alarms, history, data export, etc...) allow an easy use with optimal working conditions. They are available in two models: a single line version with sufficient purification capacity to work comfortably over time without the need for regeneration, and a double line version to secure its working environment at 1ppm without interruption.

P(sys) single line: capacities 45L O2 - 1440 gr H20

P(sys)-II-P double line: capacities 90L O2 - 2880 gr H20

H2O and O2 sensors allow continuous monitoring of the purity of the atmosphere on screen.

The whole unit is entirely controlled by a PLC with access to data control and parameter settings on a color touch screen.

You can find our detailed information on the PUREEVO and our different P(sys) purification systems on the Jacomex website.

A P300 VACUUM PRESSURE KIT

Stainless steel 300mm cubic vacuum chamber with hinged aluminum front door with two portholes for material loading in evaporation sources or maintenance operations (e.g. changing protective screens). A process door for loading substrates from the glove box. The enclosure is equipped with a set of protective screens for the internal walls of the chamber. Various connections are also provided:

- portholes,

- empty measure,

- ventilation,

- pump connection,

- free passages to install, if necessary, your measuring accessories or other accessories.

On this HV frame, the sealing is guaranteed by the use of Viton rings.

Several SOURCES OF EMPTY EVAPORATION

Each Joule source consists of a water-cooled high-current electrical passage connected to a high-current generator and a high-current passage connected to ground. In the upper part, the electrical passages include a screw mounting device for fixing either a resistive filament (tungsten...) to receive the material to be evaporated (wire), or a gondola, or an evaporation furnace. The nacelle support is compatible with nacelles up to 100mm long.

A pneumatic source cover conceals the source during the preparation of charges before evaporation. The equipment is designed to receive up to three sources.

POWER SUPPLIES Configuration

A high-current power supply required for the thermal evaporation of materials. Output power 2kW, control voltage 4V and max output current 475A. Power supply controlled by a power controller and automatically managed by the deposition controller.

SECONDARY VACUUM PUMPING SYSTEM

Dry or lubricated vane primary pump. A PFEIFFER turbomolecular secondary pump, model HiPace 300 or equivalent, pumping speed 300 l/s. Secondary isolation valve.

Pre-emptying and discharge isolation valves on the secondary pump for by-pass system, guaranteeing optimal equipment lifespan. A piloted valve for enclosure ventilation. Pressure measurement by triple Pirani / Bayard-Alpert INFICON BCG 450 gauge or equivalent, measuring range 10+3 to 10-10 mbar and a capacitive sensor for Patm detection.

THICKNESS CONTROLLER with SINGLE QUARTZ HEAD

Automatic process controller for programming, servo-control, real-time control of the deposit of different materials, combination of these materials saved in memory, deposits in sequence. Management of up to two measuring heads. Time and current stage displayed in real time on a display. A head equipped with a quartz sensor detects oscillation frequency variations as a function of the deposited mass using the MODELOCK process that improves the signal-to-noise ratio. Measuring interval 0.25 s. Resolution in thickness and speed: 0.06 Angstroms @ tooling/density = 100 with a fundamental oscillation frequency of 6 MHz.

Oscillation frequency 6 MHz. Frequency divergence limit 1.0 MHz.

Crucible cover masking the source during the preheating phase actuated by a pneumatically operated jack managed by the deposition controller.

Standard single quartz water-cooled measuring head associated with its 6 MHz oscillator by a sealed electrical passage. The quartz balance is mechanically fixed in the enclosure to ensure reproducibility of the deposits, in close proximity to the substrate. Other configurations and thickness measurement strategies can be provided.

Motorized Rotary SUBSTRATE DOOR

Installed in the upper part of the room.

PILOTING AND AUTOMATISM SYSTEM

Compact control system with touch screen PLC or equivalent integrating PLC and operator panel in one and the same device. Allows a pumping management with switching from primary vacuum to secondary vacuum in automatic with display of the working pressure in the chamber. It also guarantees safety from both a user and equipment point of view. It is, for example, impossible to supply the source if the chamber is open.

Jacomex and Alliance Concept offer the equipment combining glove box and PVD thin film deposition system adapted to your needs while respecting your budget. With several decades of experience, the two companies offer you their recognized know-how in France but also in many research institutes and companies all over the world. The design and manufacturing are carried out in France ensuring the quality required for this type of high-tech equipment.