As early as the 1970s, Jacomex actively participated with the French nuclear authorities in the establishment of a French sealing standard (Afnor M62200) and manufactured the Oxyfuit device under a CEA license. This device enables glove boxes to be tested using the method known as “oxygen purifier” in compliance with the standard.

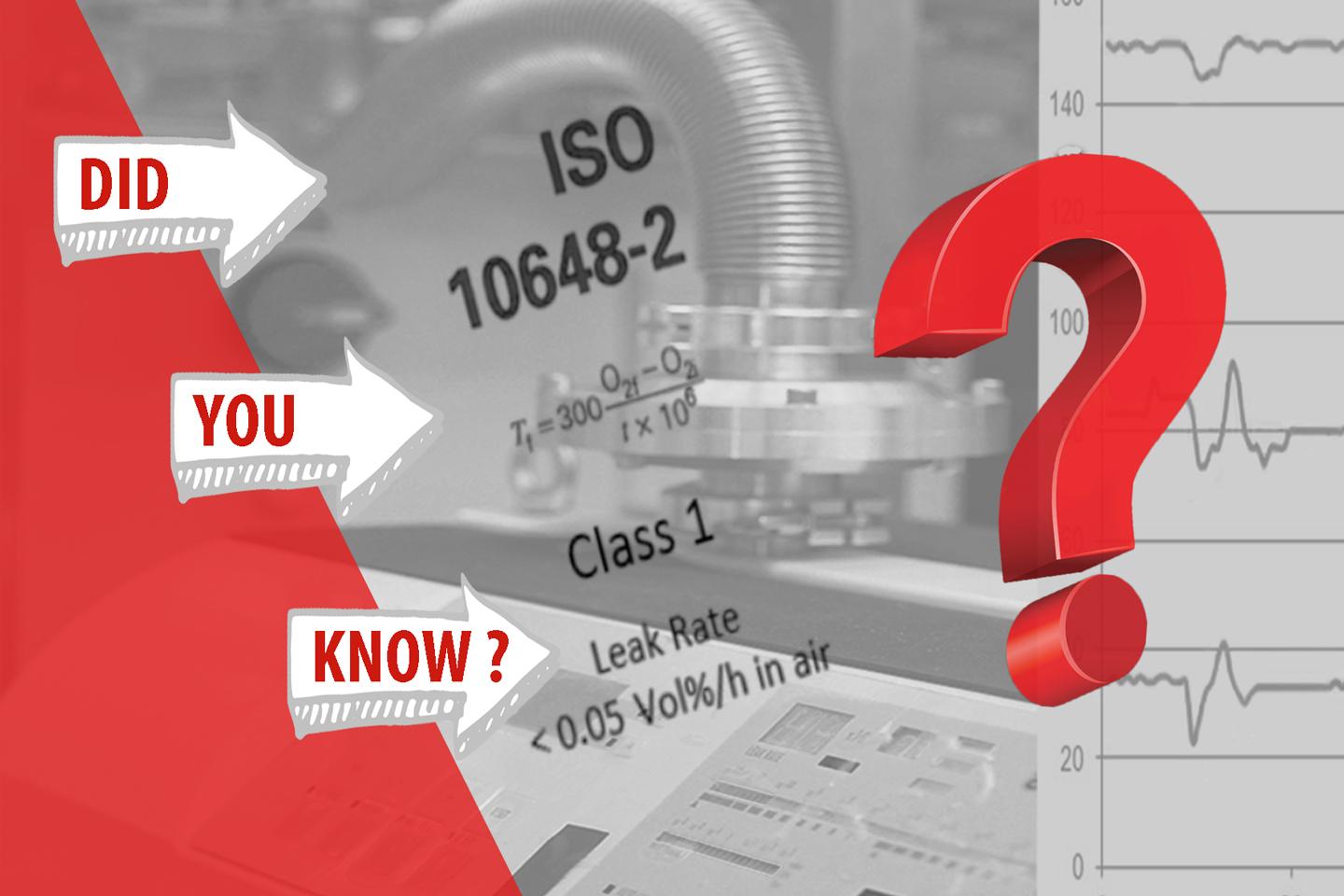

At the end of the 1980s, the company had to campaign during the development of the ISO 10648 standard to maintain rigor, especially class 1, compared to the German standard DIN 25412, that is much less strict. Today, practically all Jacomex glove boxes have the excellent Class 1.

Tests to classify containment chambers according to their tightness can be performed at various stages once the glove box is manufactured:

- Factory leakage test at the end of manufacturing and assembly

- Leakage test according to the factory standards in the presence of the user service (FAT)

- Leakage test on user site upon receipt of the equipment in the presence of the user service (SAT)

In the last two cases, the tests must be carried out in accordance with local regulations and standards in force.

Scope of the ISO 10648-2 Standard

The ISO 10648-2 standard is applied to the containment systems intended for the realization and manipulations on:

- sensitive products that require handling in a special atmosphere

- radioactive and/or toxic products to be handled inside an enclosure for the protection of the environment and/or personnel

This standard defines 3 test methods, their respective procedures and describes the test conditions to be respected. It categorizes 4 enclosure leakage classes according to their hourly leakage rate and is intended for use by suppliers, manufacturers, competent authorities and users.

As a reminder, an enclosure or glove box is specially manufactured to prevent substances from the outside atmosphere from entering the inside atmosphere, to prevent the leakage of products handled in the atmosphere under consideration to the outside atmosphere, or both.