Glove Box Operating Principle

The glove box is a closed, watertight and hermetic enclosure to separate an environment from the ambient conditions. To do this, it has a fully sealed compartment where the atmosphere can be controlled and monitored by means of built-in regulators. For glove boxes operating under gas, a purification system removes moisture and oxygen from the gas to make the process safe. The glove box also includes transparent sides equipped with handling gloves. These allow operators to handle items, products or substances without the risk of contamination or the spread of dangerous products in the environment. A transfer airlock allows the protected items to pass through without compromising containment.

Glove box operate under negative pressure or vacuum when the pressure inside its enclosure is lower than atmospheric pressure. This type of glove box is dedicated exclusively to the protection of operators and the environment. It uses a ventilation system with HEPA filters that uses ambient air from the room and extracts it to ducts after circulating through the enclosure. Thus, hazardous materials can neither come into contact with the operators nor spread in the environment. It is possible to monitor the chemical composition of the environment, gaseous emissions and leaks for maximum safety.

Examples of applications for a glove box under vacuum include: handling of hazardous pharmaceutical or chemical compounds, weighing and sampling operations, handling of pathogens or radioactive materials, reconditioning of CMR and toxic powders, powder dissolution, etc.

Which Negative Pressure Glove Box to Select?

Specialists design standard or customized glove boxes to protect operators and the environment. JACOMEX is a global reference in this sector. Specialized in the design and manufacture of containment solutions for various sectors, JACOMEX offers several vacuum glove boxes:

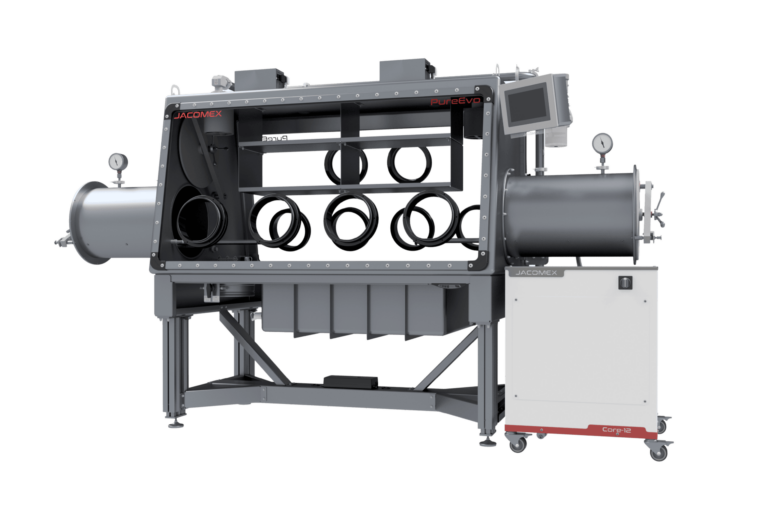

PureEvo Glovebox

This glove box is a modular model with filtered neutral gas and a self-contained purification unit. It is suitable for industrial, nuclear, pharmaceutical and advanced research applications, particularly for processes requiring the integration of instrumentation, equipment and machinery.

This glovebox is therefore ideal for securing various processes, particularly for nuclear and toxic applications which may involve operating under vacuum in a controlled atmosphere. It comes with a variety of high-capacity O2 and H2O purification systems. Like the other two gloveboxes in the PURE range (PureSmart, PureMod), it can be used for a variety of applications: synthesis chemistry, furnace processes (sintering, treatment, annealing), materials science and polymers, aeronautical welding of titanium parts, assembly and characterization of lithium-ion batteries, organic electronic materials (Quantum Dots, graphene and 2D materials, OLEDS, thin-film solar cells, etc.).

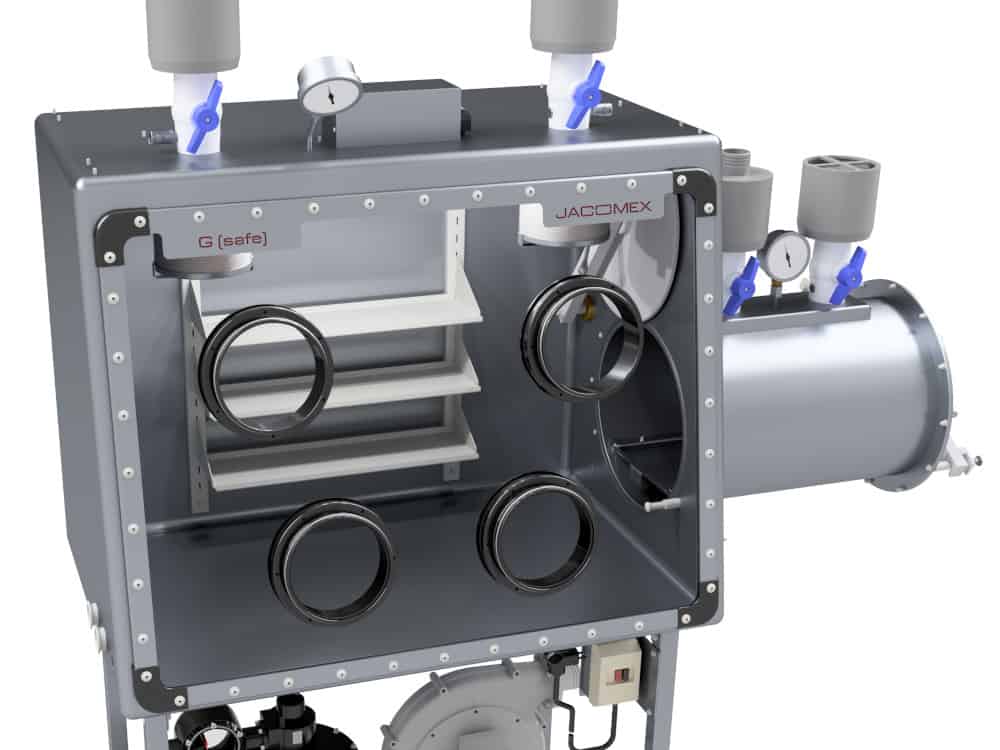

The G(Safe) Glovebox

This high-safety air-filtered glovebox enhances the safety of operators and the environment. It maintains a vacuum in the atmosphere and automatically triggers a safety flow in the event of a breach of containment. It’s also a modular model that stands out for its design and equipment flexibility. In most cases, it is designed as a single unit with rounded corners, making it easy to clean and decontaminate the internal surfaces.

To guarantee a safe air speed and automatic vacuum maintenance in the event of a glove being torn off, it is advisable to fit it with a regulation and safety valve manufactured by JACOMEX. It can be used in industry and research (toxic, CMR, nanoparticles) as well as nuclear (radiation protection).

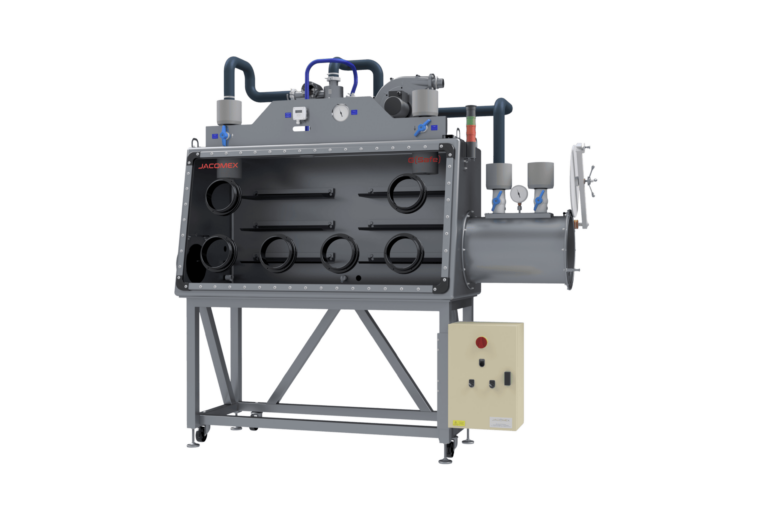

G(Iso) Glovebox

This high-safety stainless steel isolator under neutral filtered gas is adapted to the high demands of pharmaceutical and medical processes. It is custom-designed and operates in air/nitrogen vacuum.

It is ideal for protecting operators and the environment during analysis and weighing of active ingredients and CMRs, quality control, and in the manufacture of surgical and dental implants. This equipment is designed with a finish adapted to cleaning issues: bag-in-bag-out filter replacement, secure waste management, surface treatment, rounded corners.

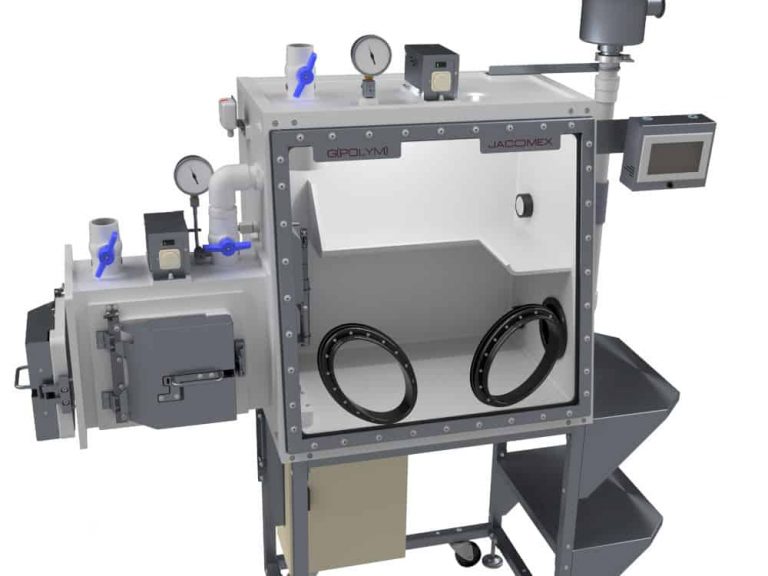

G(Polym) Glovebox

This polymer glove box is a versatile model for operator and product protection. It is available in standard sizes, but JACOMEX also offers custom-made designs. JACOMEX specializes in the manufacture of polymer (Corian) glove boxes.

This glovebox is designed for applications in molecular or nuclear biology. Its antibacterial properties, clarity and high resistance to chemicals mean you can work in total comfort. All JACOMEX glove boxes can be accessorized to suit the specific requirements of each project. Don’t hesitate to request a free, no-obligation quotation.