Regulating and Security valves for Glove Boxes

Each valve is mounted and tested individually in our site in Lyon – France. A leak test certificate as required by ISO 10648-2 is issued individually.

Their function as a valve is to ensure the constant automatic maintenance of glove boxes in a vacuum and to guarantee safe air flow in the event of sealing rupture (usually: tearing / tearing of a glove) thus avoiding any external contamination of the box.

Equipment and features

Different Types of Valves

Trusted in Leading French and International Nuclear Facilities

Recognized for their qualities such as responsiveness, reliability over time, safe mechanical operation in reference to the pressure of the glove boxes, Jacomex valves are now in operation in both French and international nuclear centers: CEA Marcoule, Atalante, Valduc, IRSN, IAEA, IRMM, CEN-SCK, Framatome, MHI-JNFL Japan, CNNC China, BARC India …

Ensuring Safety Across a Range of High-Risk Industries

Thanks to the safety they bring, the regulation and safety valves have found more and more clients in non-nuclear sectors for handling dangerous materials, where the safety of the operators and the environment can be threatened.

Consequently, Jacomex regulating and safety valves will effectively guarantee the safety of installations in various fields including process powders, weighing and repackaging of powdered powders, nanotechnologies, use of carbon nanotubes, maintenance of aeronautical parts with risk of contact with asbestos, fibers and CMR substances, cytotoxic, experiments on microorganisms and pathogenic samples…

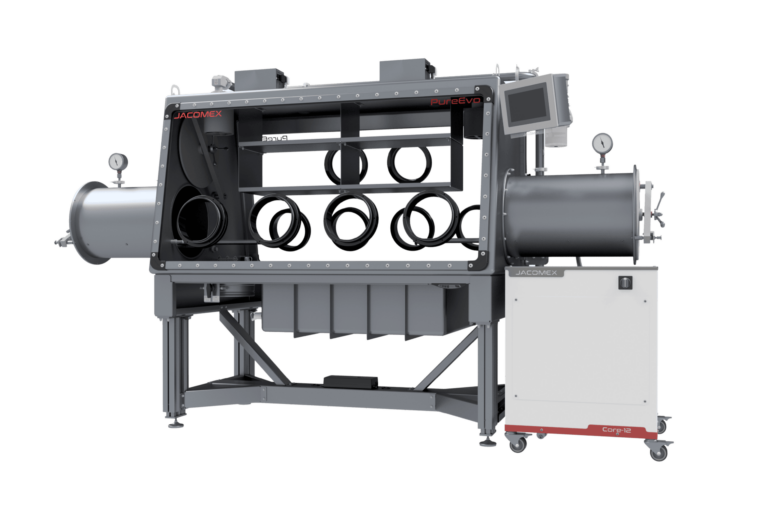

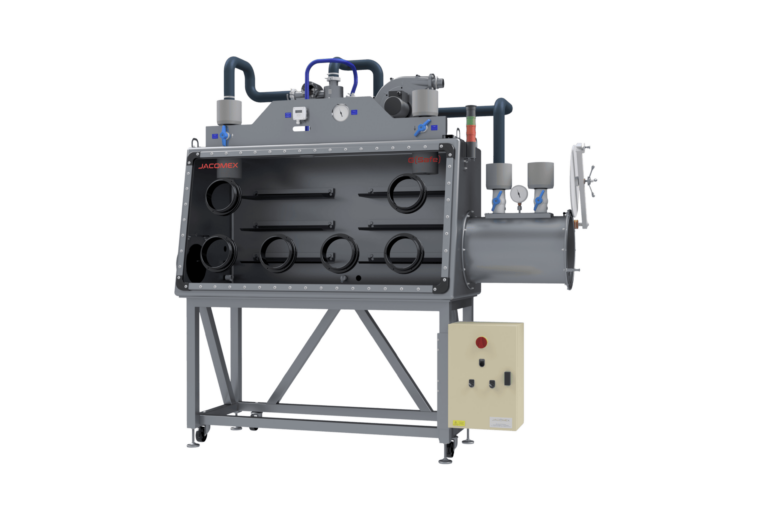

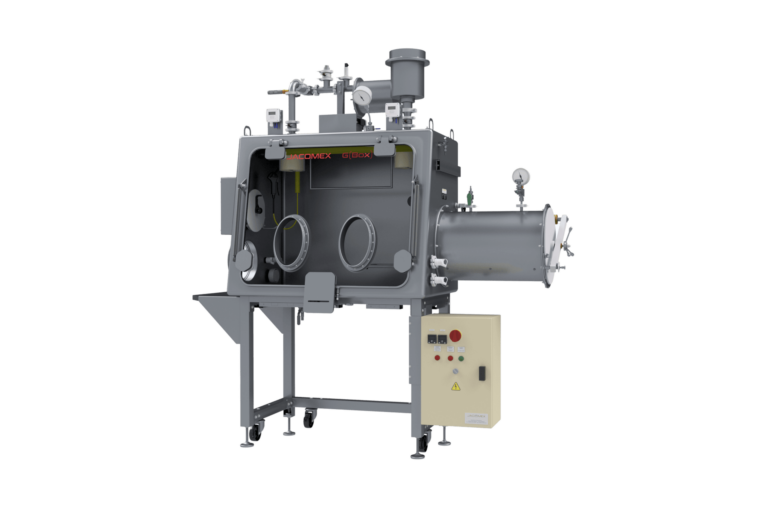

Glove boxes compatible with regulating / safety valves

They Trust Jacomex Solutions

Many customers from a variety of industries have trusted Jacomex to design and manufacture their glove boxes, insulators and air purification systems.

Have a project?

Our experts will provide you with an answer adapted to your needs as soon as possible.